Fabrication of Stainless Steel & Aluminium Products

MJW Engineering

We put the "FAB" in Fabrication

Welcome

MJW Engineering is a proudly Irish owned and operated family business that has been providing innovative steel fabrication solutions throughout Ireland and the UK for the last 30 years.

Also offering a wide selection of services, for both Commercial and Domestic, MJW Engineering cover everything across a large range of subjects.

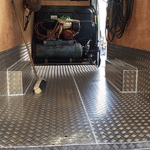

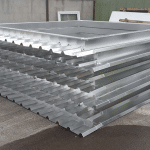

Everything from art work, stainless steel handrails, gutter facades, van linings, kitchens, bar units, sheds, storage boxes, aluminium upstands, on site welding plus much more and MJW are certain that they can produce a quality product in any situation.

Furthermore MJW Engineering – Steel Fabrication Ireland – have many years experience creating and working on different projects big and small and always achieve the highest standard possible.

Which is one of the many reasons why they are trusted by their clients. Above all else the quality of work is the statement of many years of experience and hard work.

Steel Fabrication Ireland is there when you need top quality services.

Michael J Ward - Director

Our Services

Gutter Facade

Stainless Steel Handrails

Van Lining

Artwork

Aluminium Box Seats

Insulated Sheds

Stainless Steel Kitchens

Aluminium Upstands

Request a call back

A member of our team will call you back shortly

How We Operate

Professionalism and top quality products & services in Steel Fabrication Ireland is why we are trusted by our customers.

Steel fabrication is the process of building machines and structures from raw metal materials. The process includes cutting, burning, welding, machining, forming, and assembly to create the final product.

Steel fabrication projects include everything from hand railings to heavy equipment and machinery. Specific subsectors include cutlery and hand tools; architectural and structural metals; hardware manufacturing; spring and wire manufacturing; screw, nut, and bolt manufacturing; and forging and stamping.

The main benefit of metal fabrication shops is the centralisation of these many processes that are often required to be performed in parallel via a collection of vendors. A one-stop steel fabrication shop helps contractors limit their need to work with multiple vendors to complete complicated projects.

Brilliant Ideas

Good Planning

Quick Operations

Professionalism

Safety First

Welding is the main focus of steel fabrication. Formed and machined parts are assembled and tack-welded in place, then rechecked for accuracy. If multiple weldments have been ordered, a fixture may be used to locate parts for welding. A welder then finishes the work according to engineering drawings (for detailed welding) or by their own experience and judgement (if no details are provided).

Special measures may be needed to prevent or correct warping of weldments due to heat. These may include redesigning the piece to require less welding, employing staggered welding, using a stout fixture, covering the weldment in sand as it cools, and post-weld straightening.

Straightening of warped steel weldments is done with an oxyacetylene torch. In this highly specialized work, heat is selectively applied to the steel in a slow, linear sweep, causing the steel to contract in the direction of the sweep as it cools. A highly skilled welder can remove significant warpage this way.

Steel weldments are occasionally annealed in a low-temperature oven to relieve residual stresses. Such weldments, particularly those for engine blocks, may be line-bored after heat treatment.